How to Preserve and Adjust Your Industrial Scales Effectively

How to Preserve and Adjust Your Industrial Scales Effectively

Blog Article

Enhance Your Organization Workflow With Reliable Industrial Scales

In today's competitive landscape, the accuracy of industrial ranges plays a critical role in improving general organization procedures. Precise evaluating not only mitigates pricey discrepancies throughout various fields, such as manufacturing and logistics, yet additionally makes certain conformity with rigid industry standards. As organizations seek to enhance performance, recognizing the different sorts of scales and their technical innovations ends up being essential. Nevertheless, the option process can be intricate, and the ramifications of these selections can significantly influence functional success. What factors should be considered to make sure the best devices is selected for your details needs?

Importance of Accurate Weighing

Accurate evaluating is critical in various industrial applications, as even minor discrepancies can result in substantial monetary losses and functional inadequacies. Industries such as manufacturing, logistics, and food handling rely on exact measurements to ensure product top quality, regulative conformity, and optimum source management. Inaccurate weights can cause overflow, wastage of resources, or insufficient supply, affecting earnings and consumer fulfillment.

Furthermore, exact weighing is necessary for safety and environmental conformity. In the chemical sector, inaccurate measurements can lead to inappropriate blends, resulting in hazardous scenarios or legal implications. In addition, in the food industry, exact weighing is important for adhering to dietary labeling demands, ensuring that customers get accurate details relating to the items they purchase.

The combination of reliable industrial ranges not just boosts operational performance however likewise supports data-driven decision-making. Firms that prioritize accurate considering can enhance stock monitoring, enhance supply chains, and reduce prices connected with returns and rework. For that reason, purchasing high-grade industrial evaluating services is critical for organizations aiming to maintain an one-upmanship in today's vibrant market. Exact evaluating inevitably works as a structure for operational quality and lasting growth.

Kinds Of Industrial Scales

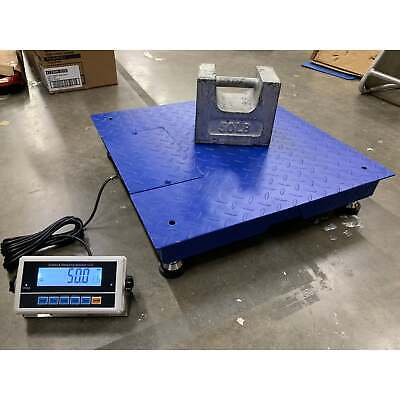

Industrial ranges come in numerous kinds, each created to satisfy specific evaluating needs throughout different sectors. Amongst the most usual types are system scales, which give a big weighing surface area suitable for hefty items, making them excellent for storehouses and manufacturing centers. These scales usually feature electronic displays for very easy reading.

One more type is bench scales, which are typically smaller and mobile, ideal for usage in laboratories or retail atmospheres. They enable quick dimension of smaller products while keeping accuracy. For applications needing the weighing of liquids, container ranges are particularly made to measure the weight of storage containers, ensuring exact supply management.

Furthermore, flooring ranges are utilized for evaluating hefty lots on the ground level, typically made use of in shipping and receiving departments. Crane ranges are additionally significant; they are suspended from a structure to evaluate hefty products in commercial setups. Lots cells play a crucial role in numerous scales, transforming pressure right into an electric signal for precise weight dimension. Each kind of commercial range offers an one-of-a-kind objective, boosting functional efficiency throughout varied sectors.

Advantages of Modern Modern Technology

Moreover, modern commercial ranges usually come equipped with connection attributes that make it possible for smooth combination with various other systems, such as stock management and production tracking. This interconnectivity cultivates an extra natural process and reduces downtime, as companies can monitor efficiency metrics and make data-driven choices immediately.

Furthermore, numerous contemporary ranges use easy to use interfaces and customizable setups, enabling operators to adjust their devices for particular operational demands. Improved resilience and resilience versus severe ecological problems even more add to the durability and reliability of modern-day scales, guaranteeing they can stand up to the rigors of commercial use.

Picking the Right Devices

Various markets may require distinctive types of scales, such as flooring scales for heavy lots, bench scales for smaller products, or portable ranges for versatility. Furthermore, considering the setting in which the scales will certainly be utilized is important. Devices used in rough environments might need to be immune and rugged to dirt, moisture, or severe temperatures.

One more critical aspect is the technology used in the scales. Digital scales usually use boosted accuracy and convenience of use, while analog scales might suffice for much less requiring applications. It is important to assess the scalability of the tools, ensuring that it can you could try here fit future development or adjustments in production processes.

Finally, businesses ought to think about the online reputation and reliability of producers, as buying high-grade equipment can result in long-lasting price financial savings and boosted operational effectiveness.

Maintenance for Durability

Routine upkeep is necessary for making check that certain the longevity and optimal performance of industrial scales. A systematic method to maintenance not only prolongs the life of the devices however likewise ensures precise measurements important for operational effectiveness.

Begin with routine evaluations to determine deterioration, guaranteeing elements such as load cells and displays operate appropriately. Calibration checks need to be performed consistently, preferably after substantial modifications in environmental conditions or following hefty use. Precise calibration is important for compliance with sector criteria and for preserving the dependability of weight measurements.

In addition, it is a good idea to establish an upkeep schedule that tapes each service see, calibration, and any fixings carried out. This documents aids in monitoring equipment efficiency and planning for future maintenance demands.

Finally, educating staff on appropriate use and care strategies will lessen the chance of operator mistake, further improving range reliability. By prioritizing normal maintenance, services can make certain that their industrial ranges continue to be a reliable possession in their procedures.

Conclusion

In summary, the assimilation of reliable industrial ranges is crucial for enhancing service procedures throughout various industries. Precise considering not just minimizes inconsistencies however additionally maximizes inventory management and guarantees compliance with market criteria. The option of ideal equipment, coupled with modern technological improvements, can dramatically boost efficiency and reduce operational costs. Regular maintenance and training further add to the longevity and accuracy of these scales, promoting data-driven decision-making and eventually supporting general company success.

Industrial scales come in various kinds, each developed to satisfy details considering requirements across various fields. Crane scales are also significant; they are put on hold from a structure to weigh hefty materials in commercial setups.Various industries might require unique types of scales, such as floor scales for heavy lots, bench scales for smaller things, or portable ranges for versatility - Industrial Scales. Digital scales frequently supply improved accuracy and convenience of use, while Visit This Link analog ranges may suffice for much less demanding applications.In recap, the integration of reliable commercial scales is crucial for improving organization operations throughout different sectors

Report this page